Includes Models: Bronco 24, Impression 24, Bronco 26, Impression 26, Outlook, Outlook DX, Peak 27.5, Mason 27.5, Overdrive 29

Open the carton from the top, and remove the bicycle. Remove the straps holding the front wheel, handlebar assembly, and the following components: Seat post with saddle, pedals and any other components. Remove the protective paper wrapping from the bicycle.

For models fitted with a quill stem, remove the protective cap from the handlebar stem and loosen the centre bolt in the head stem using a 6mm Allen key. Insert the headstem with handlebar assembly into the head tube of the bike. Re-tighten the headstem ensuring the minimum insert mark is fully covered, with both handlebars and forks facing the front. To adjust handlebars to correct angle loosen clamp bolt using 6mm Allen Key. Ensure clamp bolts are firmly retightened.

For models fitted with an Ahead stem assembly, the bearings are adjusted via an 5mm allen head compression bolt and then fastened by clamping the stem directly to the fork steerer. To assemble, remove all protective covers and unscrew bolt holding top plug. Slip handlebar stem over exposed fork steerer and replace top plug. Make sure the handlebars and fork face the front. Without over tightening, carefully tighten down the steering assembly via the Allen head centre bolt so there is no bearing freeplay. Firmly tighten up the binder bolts which clamp the handlebar stem to the fork steerer.

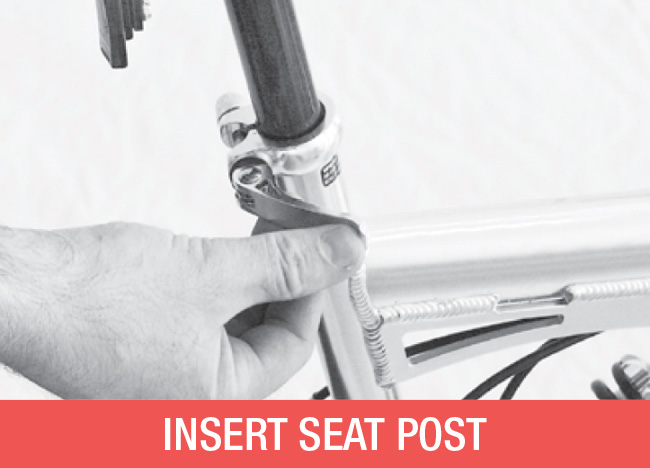

Insert the seat post with saddle into the seat tube of the bicycle, ensuring the minimum insert mark on the seat post is fully covered inside the frame. Adjust and firmly tighten the Quick Release seat tube clamp, closing the lever so it is horizontal and facing forward. If resistance is not firm, open the QR lever and tighten the adjusting nut in a clockwise direction. Close the lever and repeat if necessary.

Turn the bicycle upside down and rest it on the seat and the handlebars. Insert the front wheel into the forks ensuring that the axle fits well up against the fork end slots. For Quick Release, ensure the QR lever is open and on the left side of the bicycle. Check that the QR tension is correct; close the lever so that it is parallel to the forks. If resistance is not firm, open the QR lever and tighten the adjusting nut in a clockwise direction. Close the lever and repeat if necessary. For fork nuts, ensure that the small tab on the washer under the wheel nut is located in the slot in the forks. This tab will ensure that the wheel will not fall out should the nuts become loose. Tighten the wheel nuts using a 15mm spanner.

Attach the pedals carefully, engaging the thread initially by hand. The right hand pedal is marked with an “R” and attaches to the right crank in a clockwise direction (the right side is the one with the chainwheel). The left pedal, is marked with an “L” and attaches to the left crank in an anticlockwise direction. Tighten pedals very firmly using a 15mm spanner. Note: damage will occur if pedals are not attached in the correct direction and firmly tightened.

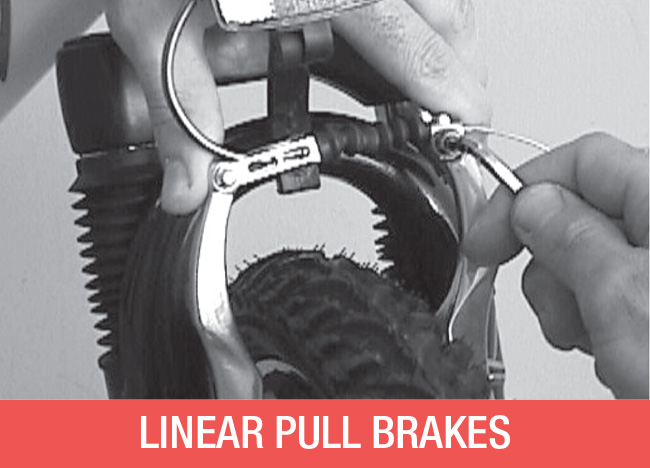

For models with linear pull/rim brakes, adjust the front brake by loosening the brake cable at the anchor bolt using a 10mm spanner. Squeeze the caliper by hand to ensure the pads sit squarely and evenly on the rim. Pull the cable tight and re-tighten the anchor bolt so that the brake pads are a maximum of 2mm from the rim on each side. Fine tune by turning the cable barrel adjuster on the brake lever. Brake shoe nuts and cable anchor must be firmly tightened. Check adjustment for rear brake and test both. Be sure that right hand brake lever operates front brake, and the left lever operates the rear brake.

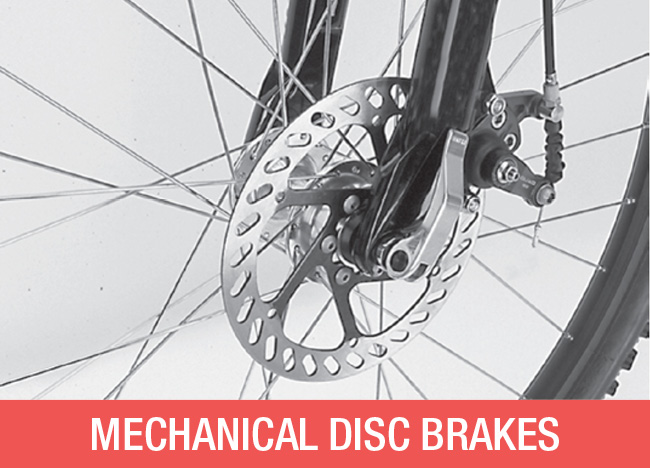

For models with disc brakes, all parts should be already attached. All components should be checked for tightness and function before riding. The bolts which hold the discs to the wheel hubs, and the bolts which fix the brake mechanism to the fork/frame must be securely fastened. Check the clearance between the disc and the brake pads. To attach the cable, insert the barrell end into the right brake lever ensuring the casing is correctly seated in the barrel adjuster. The wire at the other end is then threaded into pivot mount at the brake caliper and then through the cable anchor bolt. Some disc brakes have a centering device while others are a free-floating mechanism. If the caliper body has centering bolts, apply brake lever after cable has been connected, and tighten the centering bolts. This will centre the caliper body on the disc.

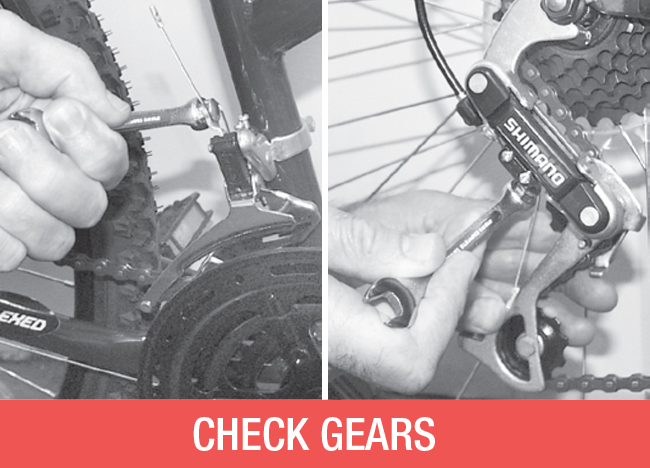

Before operating the gears, check that the 10mm anchor bolts which clamp the front and rear control cables, are firmly fastened. Only then test the gears ensuring the drive chain moves freely into each position when the control levers are activated. If further adjustments are needed, refer to the relevant section in The Owners Manual. Attach the bell to the left hand side handlebar. Attach the red rear reflector to the bracket provided and the white reflector to the front. Adjust reflectors to the 90 degree vertical position.

Important! Do not ride until brakes are operating correctly. Ensure cable end protectors are fitted, crimping with a pair of pliers. Ensure all nuts, bolts and fittings have been correctly tightened and tyres inflated to pressure written on tyre sidewalls. Ensure seat post and head stem are inserted past the minimum marks. Road test gears and adjust if needed. This bicycle must be regularly lubricated, tightened and adjusted to ensure maximum performance and safety. Proper maintenance of your bicycle ensures you will enjoy many years of happy riding. We recommend that you book your bike into a bike shop for regular services at no longer than six month intervals to ensure maximum performance.